Harland & Wolff: The Shipyard That Built Titanic – Engineering, Design, and Shipbuilding Innovations

📌 Explore the legacy of Harland & Wolff, the Belfast shipbuilders behind the Titanic and Olympic. Learn about their shipyard innovations, construction techniques, and the design philosophy that shaped the world’s greatest ocean liners. A must-read for maritime historians, educators, and genealogy researchers.

The builders of the Olympic and Titanic, the celebrated firm of Harland & Wolff, Limited, have had unrivalled experience in the construction of large passenger vessels, and the new White Star liners but add another triumph to the many which they have to their credit.

Unlike many shipbuilding firms, Messrs. Harland & Wolff may be termed builders in the most complete sense of the word. As in the case of all vessels built by them, not only have they constructed the hulls of the Olympic and Titanic, but also their propelling machinery, while much of the outfit usually supplied by sub-contractors for ships built in other yards has been manufactured in their own works.

The Shipbuilder – Harland & Wolff ⚓🏗️

Introduction: The Backbone of Titanic’s Legacy

This section of The Shipbuilder’s 1911 special issue focuses on Harland & Wolff, the legendary Belfast-based shipbuilders responsible for constructing the RMS Olympic and RMS Titanic. Unlike other shipyards, Harland & Wolff took an all-encompassing approach, overseeing not just hull construction but also propelling machinery and outfitting work. This article is an essential resource for maritime historians, students of engineering, and genealogists researching shipbuilding heritage.

From detailed technical illustrations to insights into shipyard operations, engineering challenges, and the influence of infrastructure on ship design, this publication sheds light on the industrial prowess that brought Titanic to life—long before her tragic fate.

Table of Contents For This Page

1️⃣ Introduction to Harland & Wolff

2️⃣ Design and Engineering of Titanic and Olympic

3️⃣ The Queen’s Island Shipyard – Harland & Wolff’s Facilities

4️⃣ Shipbuilding Processes and Key Facilities

5️⃣ The Role of Ship Joiners and Interior Construction

6️⃣ Influence of Speed, Passenger Accommodation, and Cargo on Ship Design

7️⃣ The Challenge of Balancing Size, Speed, and Safety

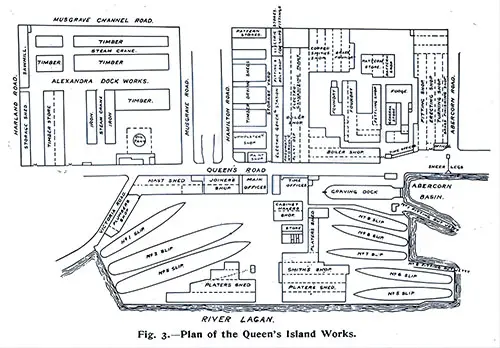

Fig. 3: Plan of the Queen's Island Works. The Shipbuilder, Midsummer 1911. GGA Image ID # 10b20489cf. Click to View a Larger Image.

Portrait of the Late Sir Edward J. Harland, Bart. The Shipbuilder, Midsummer 1911. GGA Image ID # 10b20e0d6b

Portait of the Right Hon. Lord Pirrie, P.C., LL.D., D.Sc., D.L. The Shipbuilder, Midsummer 1911. GGA Image ID # 10b25e61ac

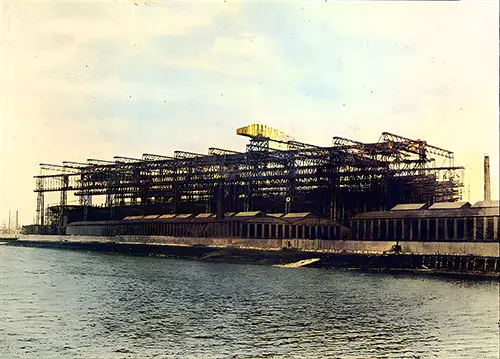

Fig. 4: General View of Gantry Over Slips Nos. 2 and 3. The Shipbuilder, Midsummer 1911. GGA Image ID # 10b2e71193

Fig. 5: Side View of Gantry Over Slips Nos. 2 and 3. The Shipbuilder, Midsummer 1911. GGA Image ID # 10b2f04116

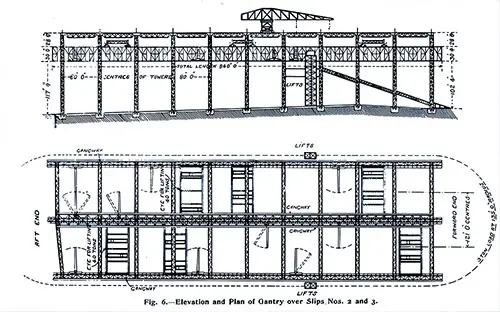

Fig 6: Elevation and Plan of Gantry over Slips Nos. 2 and 3. The Shipbuilder, Midsummer 1911. GGA Image ID # 10b2fb761d. Click to View a Larger Image.

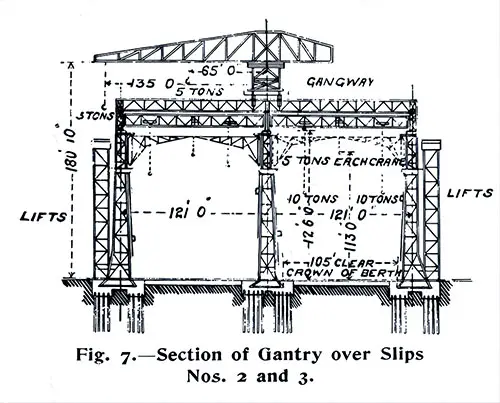

Fig. 7: Section of Gantry over Slips No.s 2 and 3. The Shipbuilder, Midsummer 1911. GGA Image ID # 10b3ab1e36

Fig. 8: Section of Gantry over Slips Nos, 5 and 6. The Shipbuilder, Midsummer 1911. GGA Image ID # 10b3daa406. Click to View a Larger Image.

Fig. 9: A Portion of One of the Platers' Sheds. The Shipbuilder, Midsummer 1911. GGA Image ID # 10b3dc886f

Fig. 10: The Mold Loft at Harland and Wolff Is a Spacious Area Where Wooden Patterns for Ship Parts Are Created. These Patterns Are Then Used to Shape Iron or Steel Components. The Shipbuilder, Midsummer 1911. GGA Image ID # 10b3e2436d

Fig. 11: A Portion of the Joiners' Shop. The Shipbuilder, Midsummer 1911. GGA Image ID # 10b49d203f

A Brief Description of the Ship Joiner’s Work

The work of the ship joiner who is employed to install joiner work of a fire-proof nature involves knowledge of metal trim, ship hardware accessories, and methods of installing special metal fittings. The ship joiner must be able to read necessary blueprints, use certain woodworking and metalworking tools, and cooperate with other tradesmen.

The ship joiner's preliminary work is laying out the locations of the various rooms, as shown on the blueprint. Measurements are taken from ship center lines. When the locations of the multiple rooms have been laid out, the necessary work done by other craftsmen may begin. The pipe fitter, electrician, ship carpenter, sheet metal mechanic, and radio man all have work to do as soon as the ship joiner's work is ready for their services.

After the quarters are tested and the iron painted, the ship joiner installs the vertical and horizontal furring or groundwork. The services of the welder and the burner are required for this installation. Still, the joiner supervises the burning and welding to ensure the work is fair and straight. One of the first operations is to install the stairs, which provide easy access from one deck to another. This is done to make working conditions less hazardous by eliminating the necessity for ladders or scaffolding. Insulation of an approved type is installed correctly and secured in place.

Intermediate bulkheads are erected. The locations of the bulkheads establish the boundary lines for rooms, bathrooms, and passages, as well as the center lines for lighting fixtures and ventilators. When other artisans have finished their work, the joiner erects shell lining and ceilings and constructs the wardrobes. The erection of bulkheads and the installation of doors require the use of self-tapping screws and a knowledge of the proper sizes of drills to use when driving certain screws in metal.

Portlight frames are set, bathrooms, rooms, and wardrobes are trimmed with the correct metal trim and properly placed according to the blueprint. This work is different from when it was done entirely in wood.

After the floors are in place, wood or metal furniture, ajar hooks, bumpers, locks, coat hooks, rods, clock pads, notice frames, and many other metal accessories are installed. Boxes and lockers of various types are fastened to the steel deck.

The ship joiner also insulates and finishes the cargo holds and constructs and insulates the ship refrigerators.

This brief description of the work involved shows that the joiner must be able to adapt himself to working in either wood or metal. Although he encounters many problems, he must give his work a clean, neat appearance since this is one of the chief objectives in joiner work.

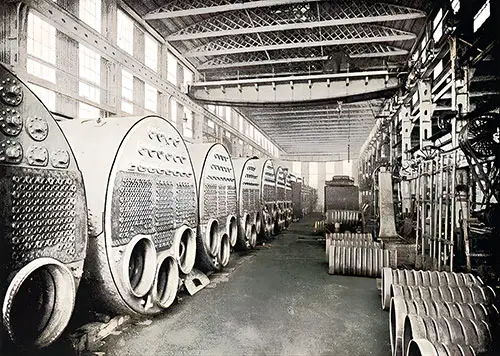

Fig 12: A Portion of the Boiler Shop. The Shipbuilder, Midsummer 1911. GGA Image ID # 10b4b8ab33

The Builders

The SS Olympic and SS Titanic were built by the renowned firm Harland & Wolff, Limited, which has unparalleled experience constructing large passenger vessels, including the new White Star liners. This latest achievement adds to the company's many successes.

Unlike many shipbuilding firms, Harland & Wolff are comprehensive builders. Both the SS Olympic and SS Titanic did not just construct the hulls but also the propelling machinery—much of the equipment that subcontractors in other shipyards typically supply was manufactured directly at Harland & Wolff facilities.

Most Important Design Factors

The two most important design factors are the speed and passenger accommodation to be aimed at. It has always been the endeavor of the competing steamship companies on the Atlantic to possess vessels that excel in one or both of these respects. The increase in the size of the ship favors both factors. Hence, the tendency to greater dimensions has been so marked during the past few years.

The maximum possible dimensions of a new vessel depend upon the dock and harbor accommodation available when the ship is completed. Lord Pirrie, among others, has devoted so much time and energy to the question of increased dock and harbor facilities, underscoring the crucial role of infrastructure in ship design and the maritime industry as a whole.

Reverting to the subject of speed, high speed is a very costly requirement, not only owing to the tremendous initial cost of the propelling machinery and the high cost of fuel on service but also on account of the necessary fineness of the ship, which limits the earning power as regards cargo-carrying and the extent of passenger accommodation.

The design difficulties significantly increase in a high-speed Atlantic liner, as the limited draught of water at the terminal ports handicaps the designer. 'Draught refers to the depth of a ship's hull below the waterline. Prudent consideration has to be given to the question of weight, as any saving that can be effected is of great value. If, on the other hand, a more moderate speed is aimed at, the problem of weight is much simplified, as the vessel can be built to a fuller model.

A greater displacement is secured without exceeding the draught available. It has been the custom of the White Star Line to strive for pre-eminence in passenger accommodation in conjunction with a speed that can be obtained without too great a sacrifice of cargo capacity, and the SS Olympic and SS Titanic have been designed under that policy.

Although a passenger on one of these vessels will not have the honor of crossing in the fastest ship on the Atlantic, he will have many compensating advantages regarding increased comfort at sea and the greater extent and variety of the accommodation provided.

Bibliography

Pennsylvania. Dept. of Public Instruction., Chester school district (Pa.)., United States. Office of Education., Sun Shipbuilding and Dry Dock Company. (1942). Ship joinery: (A manual of instruction for training beginners and for re-training wood working ship joiners for metal joiner work) ... Harrisburg: Commonwealth of Pennsylvania, Dept. of Public Instruction.

Key Highlights and Most Engaging Content

1️⃣ Introduction to Harland & Wolff 🏗️

🔹 Harland & Wolff’s reputation as a leader in large-scale passenger ship construction was unrivaled in the early 20th century.

🔹 Unlike other shipyards that relied on subcontractors, Harland & Wolff designed and manufactured most of Titanic’s and Olympic’s components in-house.

🔹 This section introduces Sir Edward Harland (co-founder) and Lord Pirrie, the driving force behind Titanic’s and Olympic’s designs.

🔹 Noteworthy Image: Portrait of Lord Pirrie 📷

📌 Significance: Lord Pirrie was instrumental in developing Titanic’s size and luxury-first philosophy, making him one of the most important figures in the ship’s history.

2️⃣ Design and Engineering of Titanic and Olympic 🚢

🔹 Harland & Wolff’s primary design considerations for Titanic revolved around size, luxury, and a balance between speed and passenger accommodation.

🔹 Emphasis was placed on ensuring Titanic was "practically unsinkable" through a double-bottom hull and multiple watertight compartments.

🔹 The balance between speed and fuel consumption was carefully considered, favoring efficient transatlantic travel over breaking speed records.

🔹 Noteworthy Image: Diagram Showing Development in Size of White Star Liners (1871-1911) 📐

📌 Significance: This visual representation of ship size evolution highlights how Titanic and Olympic represented the peak of shipbuilding progress.

3️⃣ The Queen’s Island Shipyard – Harland & Wolff’s Facilities 🏭

🔹 Harland & Wolff’s shipyard in Belfast, known as Queen’s Island, was one of the largest and most advanced in the world.

🔹 The massive gantry over slips Nos. 2 and 3, where Titanic and Olympic were built, was an engineering feat in itself.

🔹 The shipyard was self-sufficient, producing boilers, engines, and much of the ship’s interior fittings on-site.

🔹 Noteworthy Image: Fig. 3: Plan of the Queen’s Island Works 🗺️

📌 Significance: This detailed blueprint of the shipyard layout offers valuable insight into the scale and complexity of Titanic’s birthplace.

4️⃣ Shipbuilding Processes and Key Facilities 🔨

🔹 The boiler shop, plating sheds, and mold loft were critical facilities in Titanic’s construction.

🔹 The mold loft served as a crucial space for creating wooden templates that shaped steel components.

🔹 Plating sheds and joiners’ shops handled the assembly of hull plates and ship interiors.

🔹 Noteworthy Image: Fig. 10: The Mold Loft

📌 Significance: This space was key to transforming blueprints into full-scale templates, allowing for precise construction of Titanic’s steel framework.

5️⃣ The Role of Ship Joiners and Interior Construction 🛠️

🔹 Ship joiners played a vital role in outfitting Titanic’s lavish interiors, installing wood paneling, metal trim, and furniture.

🔹 Joiners worked alongside electricians, pipe fitters, and metalworkers to ensure the ship’s interior was functional and aesthetically stunning.

🔹 Portlight frames, staircases, and insulation were among the many components crafted by joiners.

🔹 Noteworthy Image: Fig. 11: A Portion of the Joiners' Shop 🏛️

📌 Significance: Highlights the complexity of Titanic’s interiors, which rivaled the world’s grandest hotels and palaces.

6️⃣ Influence of Speed, Passenger Accommodation, and Cargo on Ship Design 🚀

🔹 White Star Line prioritized passenger comfort over record-breaking speed, setting Titanic apart from competitors like Cunard’s Lusitania and Mauretania.

🔹 The balance between fuel efficiency and cargo space was key to Titanic’s commercial success.

🔹 Draught limitations at ports meant engineers had to carefully calculate how deep Titanic’s hull could extend underwater.

🔹 Noteworthy Image: Fig. 8: Section of Gantry Over Slips Nos. 5 and 6

📌 Significance: The scale of the shipyard’s infrastructure reveals how Titanic’s immense size required specialized construction techniques.

7️⃣ The Challenge of Balancing Size, Speed, and Safety ⚖️

🔹 A larger ship could offer more stability at sea, but also posed unique safety challenges.

🔹 Harland & Wolff engineers designed Titanic’s double-bottom hull and watertight compartments, which were considered revolutionary at the time.

🔹 The trade-off between weight, speed, and efficiency influenced every aspect of Titanic’s design.

🔹 Noteworthy Image: Fig. 12: A Portion of the Boiler Shop 🔥

📌 Significance: Shows the scale of Titanic’s massive steam-powered boilers, which played a crucial role in her transatlantic voyages.

Relevance for Teachers, Students, Historians, and Genealogists

👨🏫 Teachers & Students:

🔹 A rare glimpse into shipbuilding techniques and engineering principles of the early 20th century.

🔹 Perfect for STEM research projects on maritime engineering, industrial innovation, and naval architecture.

📜 Historians & Maritime Enthusiasts:

🔹 Offers authentic primary-source material on Titanic’s design, construction, and shipyard operations.

🔹 Provides context for how shipbuilding changed after Titanic’s sinking, influencing later ship safety regulations.

🧬 Genealogists & Family Historians:

🔹 Essential for researching ancestors who worked at Harland & Wolff.

🔹 Offers insight into the roles and responsibilities of shipbuilders, engineers, and ship joiners.

Encouragement for Students: Essay & Research Topics

💡 Looking for Essay Ideas?

🔹 How did Harland & Wolff revolutionize shipbuilding in the early 20th century?

🔹 What were the engineering trade-offs in Titanic’s design?

🔹 How did Titanic’s construction influence later safety regulations?

🔥 Why Use GG Archives?

GG Archives provides primary-source materials that help students and historians uncover the true history of the Titanic and the people who built her.

🚢 Step into the world of Titanic’s builders—before she became a legend. 🌊