Refrigeration on Titanic: The Cold Storage, Ice-Making, and Food Preservation Systems of a Legendary Liner

📌 Explore the state-of-the-art refrigeration systems aboard Titanic in this detailed study from The Shipbuilder (1911). Learn how food was preserved, cold drinks were supplied, and global trade was transformed by refrigerated ocean liners. A must-read for maritime historians and researchers.

The Shipbuilder – Refrigeration 🧊❄️🍽️

Introduction: The Role of Refrigeration in Ocean Travel

The Titanic and her sister ship, Olympic, were not just maritime engineering marvels; they were floating cities equipped with some of the most advanced refrigeration systems of their time. This section of The Shipbuilder (1911) provides an in-depth look at Titanic’s refrigeration system, which ensured that passengers and crew had access to fresh food, beverages, and cargo storage for long transatlantic voyages.

For teachers, students, maritime historians, genealogists, and ocean travel enthusiasts, this section provides a fascinating glimpse into how refrigeration transformed ocean liners into self-sufficient floating hotels. The technology behind cold storage and ice-making was cutting-edge for 1911, and this article showcases how it worked in remarkable detail.

Table of Contents for This Section

1️⃣ Titanic’s Cold Storage and Provision Rooms

2️⃣ The Refrigeration Plant: Keeping Food Fresh at Sea

3️⃣ Brine Circulation and Ice-Making Equipment

4️⃣ Refrigeration on Modern Liners and Cargo Ships

5️⃣ How Refrigeration Revolutionized Global Trade

6️⃣ The Importance of Refrigeration in Passenger Comfort

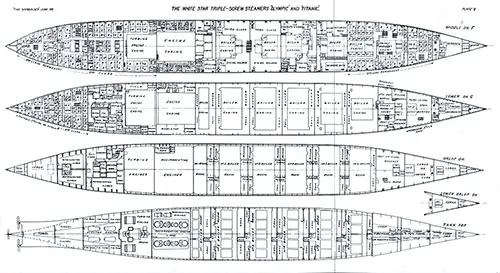

The refrigerating installation on board the Olympic and Titanic embodies all the latest facilities for efficient cold storage, ship’s provision rooms, situated aft on the lower and orlop decks (see Plate V), are most extensive, and include separate cold chambers for beef, mutton, poultry and game, fish, vegetables, fruit, milk and butter, bacon and cheese, flowers, mineral waters, wine and spirits, and champagne, which can thus be kept at the temperatures most suitable for preservation in each case.

A large insulated compartment for the carriage of perishable cargo occupies an adjacent space to the provision stores. The installation also comprises a number of cold larders in the bars and pantries in different parts of the ship and arrangements for making ice and cooling the drinking water supplied at various points in the first, second, and third-class accommodation.

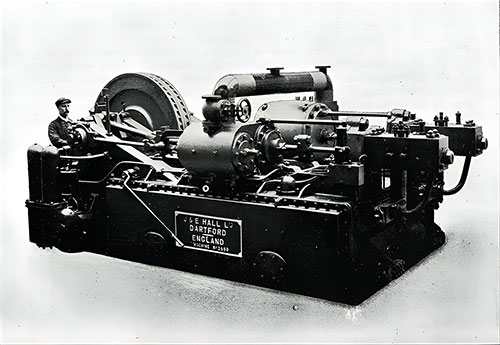

Fig. 72: One of the Refrigerating Engines. The Shipbuilder, Midsummer 1911. GGA Image ID # 10c3b2d4fb

The refrigerating engines, supplied by Messrs. J. & E. Hall, Limited, of Dartford, are a mark of quality. Situated on the port side of the reciprocating engine room at the floor level, these engines (Fig. 72) consist of two horizontal duplex C02 machines, each of which combines two complete units capable of independent working to provide four refrigerating units.

The machines, of the makers’ standard type, are built with compressors bored from solid blocks of high-carbon steel and condenser coils of solid drawn copper contained in the base casting. Each machine is equipped with its surface condenser, brass circulating pumps, and air and feed pumps, ensuring a quality and reliable operation. A duplex brass-ended water pump is provided as a stand-by, further enhancing the quality and durability of the system.

The Refrigerating Plant

This installation is of a very complete character, as in addition to cooling the insulated cargo chambers and ship’s provision chambers, and making ice, there are a large number of cold lockers in pantries, larders, etc., to be cooled, and cooled drinking water has to be supplied at a number of different points throughout the 1st, 2nd, and 3rd class accommodation.

The insulated cargo chambers and the provision chambers are both situated in the after ‘tween decks, the provision rooms being of a very elaborate char- acter and fitted up in accordance with the standard requirements of the White Star Line. A separate sel of rooms is provided for the restaurant.

The cooling duty is performed by two duplex CO, machines, each half of either machine being capable of independent working, so that there are actually four refrigerating units on each of these vessels. The plant has a total ice melting capacity of 84 tons.

The machines are of Messrs. J. and E. Hall’s standard horizontal marine type, each having a pair of CO, compressors bored from solid blocks of high carbon steel and driven off the tail rods of a com- pound steam engine.

The crankshaft is in two pieces with flanged couplings and the steam connexons are arranged so that either half of the machine may be run independently of the other if necessary.

The CO. condenser coils, of solid drawn copper tube, are contained in the cast iron box bed which carries the compressors, and the steam engine ; a separate set of coils being provided for each half of the machine and the box bed divided in the center to form two separate condenser casings.

Each machine has its own steam surface condenser, and a water circulating pump of gunmetal, and air and feed pumps are driven off its crankshaft. A separate water circulating pump of the duplex type is also provided as a standby for either machine. The two machines are arranged at the port side of the reciprocating engine room at the starting platform level.

The evaporators, which are divided into four units, are placed in an insulated room above the machine, at the orlop deck level, and three brine pumps of the vertical duplex type are also placed on this level. The brine return tanks are placed at a higher level immediately above the evaporators. The brine circulation is on the open return system with separate flow and return on each circuit.

The brine pipes for cooling the insulated chambers and the various cold lockers, etc., are of wrought iron electrically welded into grid form and galvanized externally. The circuits in the chambers are of moderate length and are interlaced to ensure an even distribution of the cooling effect, even in the remote contingency of one section becoming blocked. The brine connecting piping is also externally galvanized. There are two ice-making tanks, fitted with rocking gear driven by an electric motor.

The cooling accessories consist of a large number of water coolers, bottle coolers, cold cupboards and larders in the pantries, bars, etc., in different parts of the vessel.

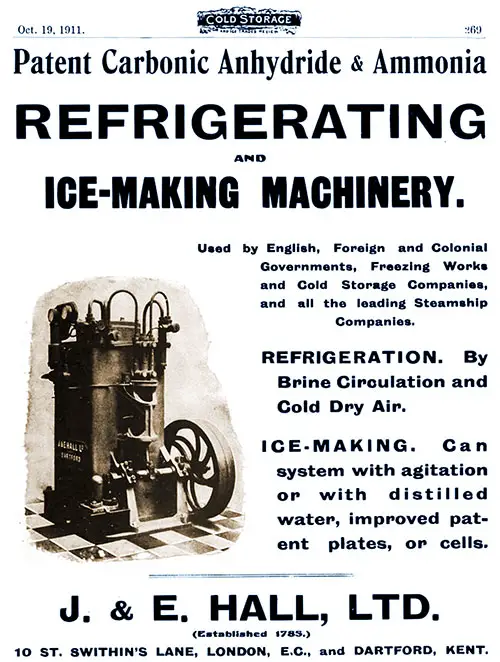

Brine Circulation and Ice-Making Equipment From the Era of the Titanic. Patent Carbonic Anhydride & Ammonia Refrigerating Amd Ice-Making Machinery. by English, Foreign and Colonial Governments, Freezing Works and Cold Storage Companies, and All the Leading Steamship Companies. Refrigeration. by Brine Circulation and Cold Dry Air. Ice-Making. Can System With Agitation or Distilled Water Improve Patient Plates or Cells. Used J. & E. Hall, Ltd. (Established 1785.) London, E.C., and Dartford, Kent. Cold Storage, 19 September 1911. GGA Image ID # 223fd31313

Plate V: Deck Plans of Middle, Lower, Orlop, Lower Orlop, and Tank Top Decks of the White Star Tiple-Screw Steamers "Olympic" and "Titanic." Layout of Provision Rooms is on the Lower and Orlop Decks The Shipbuilder, June 1911. GGA Image ID # 223fc5b577. Click to View a Larger Image.

Refrigeration on Modern Liners

During the last ten years, the accommodation for passengers on the regular liners, both British and foreign, has undergone significant development and elaboration. The number of public rooms provided for each class of passenger has increased. The decorations and equipment for first-class passengers are on par with those of hotels of the highest class, with the catering being comparable to that of the Ritz or Carlton Hotels.

On many of the larger liners, there are two complete catering systems. The passenger has his choice between a ticket covering complete victualling for the voyage or one which includes his room and attendance, leaving him free to take his meals a la carte in a separate restaurant. The service of the two departments is quite distinct, with individual kitchens, pantries, and stores, including cold storage, and two sets of insulated chambers for the various classes of provisions.

The refrigerating installation on such vessels is necessarily elaborate, designed for maximum reliability. As there are generally some cargo chambers for special consignments of high value, such as game and fruit, there are seldom less than two duplex machines, and in some cases three, each capable of separate working but having cross connections to afford complete protection in the case of any temporary disablement of a unit.

The largest vessel in the world, the Hamburg Amerika liner Imperator, which recently completed its first round voyage, has an installation supplied by J. and E. Hall, Ltd., of London and Dartford. It consists of three duplex machines.

The brine circulation for the saloon, restaurant stores, and cargo chambers is exceptionally complete and capable of very fine adjustment of the temperatures required in the various chambers of the vessel.

The great White Star liner, now in stock, will have two of Hall's large duplex machines and brine circulation arranged similarly to that which has proved highly successful in practice at the Olympics.

The new mail steamers of the improved "A" class, now building for the Royal Mail Steam Packet Company's South American service, will be fitted with a large machine of the duplex type, and this plant, which, besides dealing with the complete set of provision rooms, has an exceptionally large margin of power for enabling it to cool a considerable cargo of chilled beef.

The brine circulation is on the makers' unique three-temperature system, proving its reliability and efficiency on the vessels of the "A" and "D" Classes in this great company's service.

Apart from that, the Dartford firm supplied and fitted some highly interesting installations for meat importation on vessels that do not carry cabin passengers. Among these may be mentioned the El Uruguayo, La Rosarina, and La Negra of the British anti-Argentine Steam Navigation Company, which are included in the half-dozen largest installations afloat.

Fig. 2 illustrates the general arrangement of the chambers on these vessels. It shows the large number of separate chambers provided, the temperature of each of which can be separately controlled with a maximum variation of about half a degree.

The refrigerating machinery on these vessels consists of two large, entirely separate units driven by tandem compound engines.

Among installations of more moderate size may be mentioned the Adelaide, Melbourne, and Hobart of the German-Australian Line, which trade between Australian ports and the Continent. On these vessels, the holds are adapted alternately for meat and apple cargoes.

They are provided with air-cooling batteries, which are essentially heat exchangers that use air to remove heat from the cargo, and power-driven fans, which circulate the cooled air to maintain the desired temperature.

Refrigeration on Ocean Steamships

By C. J. BECK, Freight Traffic Manager, Hamburg-American Line.

Other than steamships themselves, there is, perhaps, no facility so important a factor in the growth of the world’s water-born commerce as refrigeration. It has opened up a vast field of activity in the interchange between nations of products essential to the well-being and happiness of humanity, has cheapened the cost of necessities to the masses, and added to the luxuries of the classes.

It has made travel by sea a pleasure instead of an ordeal and added infinite comfort to the lives of that great body of men who have chosen the sea for their calling.

Refrigeration in its simplest form can be found on practically every vessel afloat, and there are 843 vessels fitted with insulated chambers and refrigerating machinery.

The majority of these vessels thus equipped only to carry fresh food supplies for their passengers and their crews, but as the modern trans-oceanic liner not infrequently has 4,000 to 6,000 persons to feed on a single trip, its cooling equipment must, of necessity, be extensive.

For the average ocean traveler, the sight of the refrigerating chambers on a large liner is a revelation. The abundance of fresh produce, meats, and beverages neatly stored in crates, barrels, and boxes is a testament to the convenience and luxury that refrigeration brings to ocean travel.

Here may be found crates, barrels, and boxes of vegetables, crates of eggs, tubs of butter, sides of beef, mutton, fish, fowl, wines, and other beverages—everything to satisfy the ravenous and appeal to the fastidious. Thanks to modern methods of refrigeration, all are as fresh and fit for the table as the day they were taken on board.

What this means to the traveling public can scarcely be realized except to those whose memories go back to journeys taken before the art of refrigeration on ocean steamships had reached its present stage of comparative perfection.

Yet, the true value of refrigeration in ocean transportation lies not in its ability to enhance travel comfort, but in its role in reducing waste. By providing a means for the distribution of perishable and semi-perishable products, refrigeration helps prevent these goods from being disposed of in unprofitable markets or worse, going to waste.

Refrigeration has revolutionized the meat trade, with a vast fleet of steamships now carrying surplus meats from countries like the US, Canada, Argentina, and Australia to the densely populated markets of Europe. This shift from shipping livestock on the hoof to using refrigeration is a clear sign of the economic benefits and future potential of refrigerated ocean transportation.

Next in the order of importance comes the fruit trade, to which refrigeration has opened up almost unlimited possibilities. Owing to its variety and the peculiarities of the seasons, fruit is a product of export and import with nearly all lands, and with few exceptions, its transportation over the oceans in refrigerated space is either necessary or economically desirable.

Experience is daily proving that the additional cost of a refrigerated room is more than offset by the better prices realized as a consequence of the greatly improved condition in which the fruit is delivered to the consumer, and the demand for cooled space is constantly increasing, both in diversity and volume.

A few years ago, bananas from the West Indies and Caribbean countries to the United States were carried almost entirely in naturally ventilated ships; today, the bulk of the movement is in refrigerated vessels, and even on short voyage routes, the fruit shippers have found it advantageous to supplant the old type naturally ventilated carrier with modern refrigerated vessels.

The value of refrigerated ocean transportation to the fish and dairy industry is obvious. Another trade from which it has greatly benefited is beer from Germany. This commodity is received by the steamship at the shipping port directly from iced cars or refrigerated barges.

It arrives at the port of destination in condition for direct delivery to the retail trade, thus saving the heavy expense of warehousing and conditioning that would be necessary if it were shipped in ordinary space.

Refrigerated ships open many trade opportunities. This article does not attempt to cover the whole field; its purpose is to bring to the attention of those interested in the forward strides made in refrigerated transportation by ocean steamships and point out a few of its varied possibilities.

Many shippers of semi-perishable products would do well to experiment with this method of transportation, for its benefits are by no means confined to quickly deteriorating commodities. A glance into one’s household refrigerator might prove enlightening, and one will find convincing evidence of the theory that refrigerated transportation in ocean steamships is today but in its infancy.

Bibliography

"Refrigeration on Modern Liners," Cold Storage and Produce Review, London: Joseph Raymond, Vol. XVI, No. 184, 17 July 1913, pp. 174-175.

C. J. Beck, "Refrigeration on Ocean Steamships, The Butcher's Advocate and Market Journal, New York-Chicago: The Butcher's Advocate Company, Vol. 56, No. 11, 7 January 1914. pp. 20-21

Key Highlights and Most Engaging Content

1️⃣ Titanic’s Cold Storage and Provision Rooms 🍖🦞🥬

Titanic featured separate cold storage rooms for various food items, including:

🔹 Beef, mutton, poultry, and game

🔹 Fish, vegetables, fruit, milk, and butter

🔹 Bacon, cheese, champagne, wine, and spirits

🔹 Even flowers had their own refrigerated space to maintain freshness!

These storage rooms were strategically located in the lower and orlop decks to maintain a stable temperature and reduce heat exposure from upper decks.

🔹 Noteworthy Image: Plate V: Deck Plans of Middle, Lower, Orlop, and Tank Top Decks

📌 Significance: Shows the exact layout of Titanic’s provision rooms, highlighting how food was stored efficiently for thousands of passengers and crew.

2️⃣ The Refrigeration Plant: Keeping Food Fresh at Sea ❄️

Titanic’s refrigeration system was one of the most advanced of its era, with:

🔹 Two duplex CO₂ refrigerating machines (essentially four units, providing backup in case of failure).

🔹 A total ice-making capacity of 84 tons, ensuring an ample supply of ice for cold drinks, food preservation, and onboard cooling.

🔹 Cold lockers in pantries and larders across all three passenger classes, ensuring that fresh food was available for everyone.

🔹 Noteworthy Image: Fig. 72: One of the Refrigerating Engines

📌 Significance: Highlights the powerful refrigeration equipment used to maintain Titanic’s high standards of onboard dining and food storage.

3️⃣ Brine Circulation and Ice-Making Equipment 🧊

Titanic used brine circulation to cool storage rooms and pantries, an advanced technique that ensured:

🔹 Even temperature distribution throughout the ship.

🔹 Efficient cooling in all storage areas, reducing food spoilage.

🔹 Reliable operation, even if one section of the system malfunctioned.

The brine pipes were made of wrought iron, electrically welded into grid formations for uniform cooling.

Titanic also had two ice-making tanks with rocking gear to produce fresh ice throughout the voyage.

🔹 Noteworthy Image: Brine Circulation and Ice-Making Equipment from the Era of the Titanic

📌 Significance: Demonstrates the cutting-edge refrigeration technology of the time, which was critical for preserving perishable goods during long voyages.

4️⃣ Refrigeration on Modern Liners and Cargo Ships 🚢

🔹 As passenger ships became larger and more luxurious, their refrigeration systems became more sophisticated.

🔹 Ships like the Imperator (Hamburg-Amerika Line) had three large duplex refrigerating machines, allowing for precise temperature control in different sections.

🔹 Cargo ships carrying game, fruit, and dairy products were outfitted with massive refrigeration units to safely transport perishable goods across oceans.

🔹 Noteworthy Article: Fig. 2: Refrigeration Equipment on Cargo Vessels

📌 Significance: Shows how refrigeration expanded beyond passenger liners to cargo shipping, revolutionizing global trade.

5️⃣ How Refrigeration Revolutionized Global Trade 🌎

Before refrigeration, transporting fresh meat, dairy, and fruit across oceans was almost impossible.

Refrigerated cargo ships changed the global economy by allowing:

🔹 Fresh meat exports from the U.S., Canada, Argentina, and Australia to Europe.

🔹 Fresh fruit shipments, such as bananas, from the Caribbean to the U.S.

🔹 Refrigerated beer exports from Germany to overseas markets.

🔹 Noteworthy Image: Refrigeration in Ocean Steamships by C.J. Beck

📌 Significance: Highlights how refrigeration transformed trade, making fresh food available worldwide.

6️⃣ The Importance of Refrigeration in Passenger Comfort 🍷🦐

Refrigeration wasn’t just for food storage—it enhanced the luxury of ocean travel:

🔹 Chilled wines, spirits, and mineral waters were available in Titanic’s lavish dining rooms.

🔹 Fresh dairy and produce meant first-class passengers enjoyed fine dining comparable to the Ritz or Carlton hotels.

🔹 Even third-class passengers had access to fresh, properly stored meals, a huge improvement over earlier steamship travel.

🔹 Noteworthy Image: Titanic’s Cold Storage Layout in Plate V

📌 Significance: Demonstrates how refrigeration was integral to the Titanic’s reputation as a floating palace.

Relevance for Teachers, Students, Historians, and Genealogists

👩🏫 Teachers & Students:

🔹 This section is an excellent resource for STEM lessons on thermodynamics, refrigeration, and engineering advancements.

🔹 Great for historical essays on how refrigeration changed travel and global trade.

📜 Historians & Maritime Enthusiasts:

Offers rare insights into early 20th-century shipboard refrigeration and how ocean liners were self-sustaining for long voyages.

🧬 Genealogists & Family Historians:

For those researching ancestors who worked as ship’s cooks, stewards, or refrigeration engineers, this section provides context on their daily work and responsibilities.

Encouragement for Students: Essay & Research Topics

💡 Need Research Ideas?

🔹 How did Titanic’s refrigeration system compare to modern cruise ships?

🔹 What impact did refrigerated cargo ships have on the global economy?

🔹 How did refrigeration contribute to Titanic’s luxury and passenger experience?

🚢 From ensuring fresh gourmet meals to revolutionizing global trade, refrigeration played a crucial role in making Titanic a legend. 🌊❄️